Home • Water Treatments • Reverse osmosis (RO)

Reverse Osmosis (RO)

The reverse osmosis is a process that guarantees the production of water with a high chemical and biological quality. The process is based on a physical aspect in accordance to the application of a higher hydrostatic pressure than the osmotic pressure that exists between two substance containing solutions with different concentration and separated by a semi-transparent membrane, which permits the passage of water from a solution with a higher concentration of solutes to a solution with a lower concentration.

The Cullwater reverse osmosis equipments using the property of particular semi-permeable membranes where the pores, with a diameter of 5 A° (0.0005 micron) and elevate pressure (> 8 bar) let them cross by the molecules of water and not by the salts, preventing from the passage of bacteria, pyrogenic and organic substances representing the most sophisticated and efficient technology for the elimination of salts and other substances present in the water. The Cullwater reverse osmosis equipments are completely built in stainless steel.

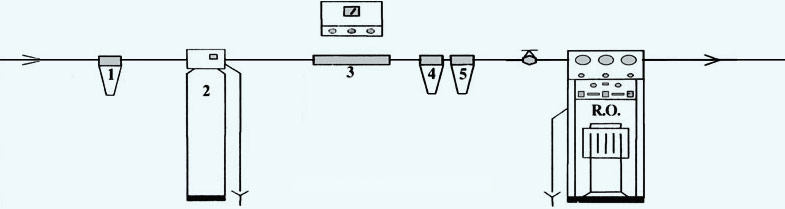

Description of the pre-treatment's system Cullwater*

The unrefined water has a first pre-treatment of mechanic filtering with 20 micron in order to eliminate every parcels of suspension, then a second pre-treatment of softening for the elimination of the alkaline-earth salts. The third pre-treatment is sterilization with UV rays for a bacterial decontamination, a fourth with an active carbonate filtration for the elimination of chlorine substances and a fifth pre-treatment with mechanical filtering with 5 micron for the elimination of every parcels of carbonate in suspension. At the end the completely pre-treated water, is ready for the reverse osmosis treatment in order to reduce the salt to value suitable for the final use. Cullwater builds for hemodialysis centres, pharmaceutical industries, photographic industries, cosmetic industries, laboratories of research and analysis.

* The correct pre-treatment of water remains to be evaluated each time on the basis of the chemical-physical characteristics of the water to be treated.

Technical features of reverse osmosis equipments

| Model | Production l/h* | Connections IN/OUT | Electric Power | Power in kW | Dimensions in mm. | Osmotic membranes | Shipping weight kg. | |||||

| L | P | H | ||||||||||

| RO 95 | 95 | 1/2″ | 220 V – 50 Hz | 0,25 | 1200 | 500 | 500 | 1 x 2540 | 26 | |||

| RO 200 | 200 | 1/2″ | 220 V – 50 Hz | 0,37 | 1200 | 500 | 500 | 2 x 2540 | 34 | |||

| RO 300 | 300 | 1/2″ | 220 V – 50 Hz | 0,37 | 1200 | 500 | 500 | 3 x 2540 | 42 | |||

| RO 390 | 390 | 1/2″ | 220 V – 50 Hz | 0,55 | 1200 | 590 | 500 | 4 x 2540 | 50 | |||

| RO 550 | 550 | 1″ | 220-380 V – 50 Hz | 1,10 | 915 | 615 | 1800 | 2 x 4040 | 110 | |||

| RO 800 | 800 | 1″ | 220-380 V – 50 Hz | 1,10 | 915 | 615 | 1800 | 3 x 4040 | 150 | |||

| RO 1000 | 1000 | 1″ | 220-380 V – 50 Hz | 1,10 | 915 | 615 | 2560 | 4 x 4040 | 190 | |||

| RO 1450 | 1450 | 1″ | 220-380 V – 50 Hz | 1,50 | 915 | 615 | 2560 | 6 x 4040 | 220 | |||

| RO 2100 | 2100 | 1″ | 220-380 V – 50 Hz | 1,50 | 915 | 615 | 2560 | 8 x 4040 | 260 | |||

*TEST CONDITIONS: Pressure 8 – 10 bar – Temperature 20 °C – TDS < 1500 ppm – SDI < 5 – NTU < 1 – Salt rejection 97-99%.

The production capacity of each individual system depends on the operating conditions to which it is subjected, such as pressure, temperature and chemical-physical characteristics of the incoming water.

WORKING DATAS

|

||||||||||||