In response to a request from a company producing fuel cells, for which a whole series of supplies of components and systems for water treatment had already been made in the past, a specific system was engineered and installed for the production of osmotized / demineralized water starting from aqueduct water.

The water leaving the treatment plant is destined within the plant for the production of fuel cells and the related laboratory test benches.

The operating logic of the water treatment plant we created consists in the production of osmotized water, with an electrical conductivity < 20 μS, to be stored in a tank and from which an autoclave group draws for subsequent pressurization to the users, after passing over a mixed bed resin bed for a reduction of the conductivity < 1 μS.

In order to make the system as versatile as possible (also for future needs of the company) water intakes have been set up for sending to the users only softened or osmotized water.

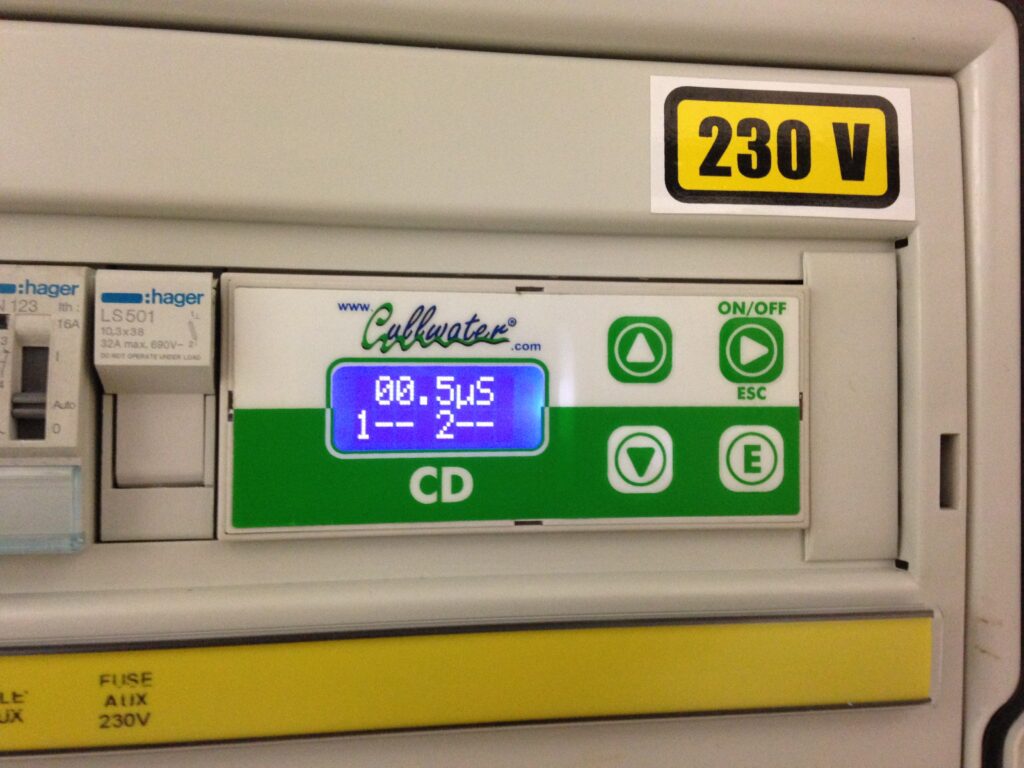

The quality of the water produced is controlled in-line by conductivity meters installed on board the reverse osmosis system and inside the electrical control panel, as regards demineralised water.

The water treatment consists of the following stages:

- Self-cleaning filter mod. Eco Fam SA, with 90 μ stainless steel filter cartridge

- Volumetric cabinet water softener mod. VC 1035 30A

- Cartridge filter mod. F 10, with 1 μ PP filter cartridge

- UV-C sterilizer, mod. QZ 600

- Reverse osmosis desalination system mod. RO 60

- 500 lt. PE water storage tank, equipped with float switches

- Pressure pump

- Mixed bed demineralizer mod. D 1044

- General electrical control panel for the control and electrical protection of the single water treatment units, pressure pump and float switches

A final conductivity meter allows in-line monitoring of the water supplied by the system and sent to production, allowing the operator to intervene or schedule periodic maintenance interventions on the system in advance.